Wood Fuel Storage

Fuel storage facilities normally account for a significant proportion of the overall capital cost of biomass heating system. It is important to size fuel storage on the site heat demand and demand profile.

A message from a sponsor

Biomass Boiler Wood Storage Volume

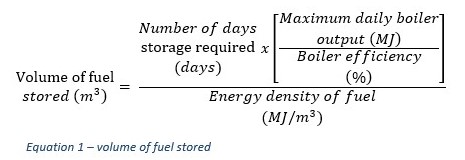

The volume required to store the fuel can be estimated using the following formula:

Breaking this formula into three parts, there are four steps to follow:

Step 1 is to calculate the number of days storage required.

Assuming a 32-week heating season between October and April and a limit of 4 fuel deliveries (3 winter fills and 1 summer fill), then an 8 week supply or 40 days storage (8 weeks x 5 days) is required. This period could be extended to reduce the number of deliveries per annum provided space is available, and the days adjusted to match plant operational days.

Manufacturers will state a boiler efficiency around 88% to 94%. However the system efficiency will range anywhere between 55% and 90%. A well designed and maintained system with plant selection optimised for the heat load should have an efficiency >80%.

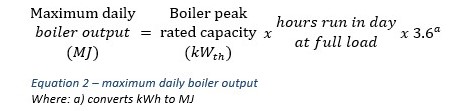

Step 2 calculate the maximum daily boiler output using equation 2.

Note that the 'hours run in day' will be based on the estimated duty profile of the biomass boiler. So, if a boiler is 'on' for eight hours in a day, this may not represent a continuous load at full capacity (e.g., start-up time). Some allowance should be made for this.

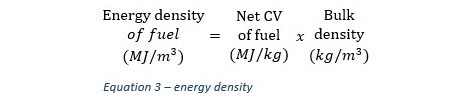

Step 3 calculate the energy density of the fuel (the amount of energy stored in the chosen wood material per unit volume) using equation 3.

Step 4. Finally having established the three parts of the formula, calculate the volume of the fuel stored using equation 1.

For the final store size make due allowance for minimum delivery volume and 'dead space' capacity.

Annual Fuel Usage

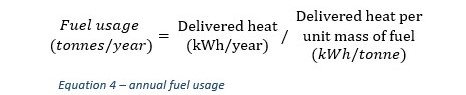

The annual fuel used can be estimated from equation 4:

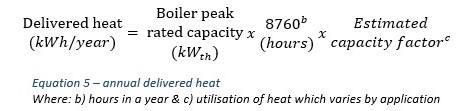

The delivered heat from the biomass plant can be estimated as a function of its peak-rated capacity and the estimated annual load using equation 5:

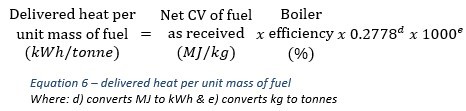

The delivered heat per unit mass of fuel is dependent on the boiler efficiency and the CV of the fuel. It can be calculated using equation 6:

Calorific Value

The Calorific Value (CV) indicates the heating potential of a fuel and is a measure of its energy content. Approximate values:

- Wood Chip CV 3.5 kWh/kg (12.6 MJ/kg)

- Wood Pellet CV 4.7 kWh/kg (17 MJ/kg)

Bulk Density

Approximate bulk density (weight per unit volume) is:

- Wood pellets 650 kg/m³

- Woodchips 230 kg/m³

That is, pellets are roughly 3x heavier than wood chips for the same storage volume.

Moisture Content

Wood with a high moisture content (MC) provides less energy. MC can vary from 5-8% for wood pellets to 35% for conditioned woodchip and up to 65% for freshly felled timber.

Conversions

1 kilowatt-hour (kWh) = 3,600kJ

Multiply kWh by 3.6 = MJ

Multiply MJ by 0.2778 = kWh

Capacity Factor

This is the ratio of the actual output (of a heating plant) over a period of time and its output if it had operated at full capacity for the same period of time. For general occupancy (use during working hours) use 0.2 (20%).

Volume & Weight

Volume occupied by 1 tonne

- Wood pellets fill approximately 1.5m³

- Woodchips fill approximately 4.0m³

A message from a sponsor

Wood Fuel Storage id: lzc-08 (v.7.0)