Ground Source Heat Pump (GSHP)

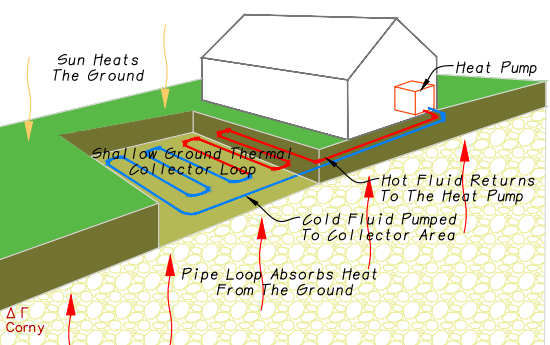

Ground source heat pumps utilise low temperature geothermal energy (solar energy absorbed by the ground). Ground Source Heat Pumps take heat from the ground by circulating fluid in buried below ground thermal collector pipes. The fluid then passes through a heat exchanger into a heat pump. A compression cycle raises this low grade heat to a higher temperature capable of heating water for property heating and hot water circuits.

Working in a similar fashion to refrigerators these systems are best suited to provide a constant, lower level, of heating without sharp peaks in temperature and therefore ideal for serving underfloor heating systems.

A message from a sponsor

Heat from the Earth

A GSHP system consists of a ground source heat exchanger, heat pump, and a heat distribution system. Water is pumped through the heat exchanger that consists of pipes buried either horizontally or vertically in the ground. The water temperature present in these pipes is lower than that in the surrounding ground. As a result, heat is transferred through the pipes warming the circulated water. The captured low grade heat is transferred to the heat pump to heat up a refrigerant. The 'warmed' refrigerant is compressed increasing its temperature. The higher temperature refrigerant in turn heats a secondary water circuit to a higher temperature.

The result is an output temperature of 35 °C-45 °C. This is ideal for underfloor heating in a solid floor construction. Heat pumps can achieve a temperature of 60 °C but at a reduced efficiency output.

In small properties with heat losses exceeding 10 kW, GSHP’s should be considered in favour of ASHP’s as their performance does not suffer reduction in cold extremes.

Performance

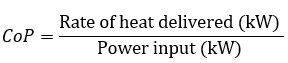

The coefficient of performance (CoP) is the key measure of heat pump performance. GSHP systems are highly efficient, delivering 300-400% efficiency (CoP 3.0-4.0) against 86% typically seen with condensing gas boilers.

A CoP between 3.0-4.0 means for every 1 kW of electricity used to power the system, 3-4 kW heat output is delivered.

The CoP will vary according to the amount of heat that is exchanged to the water circulated in a building heating system. The heat pump will have to work harder to provide a higher hot water temperature.

Always check the equipment data on CoP and cross check against other suppliers as there can considerable variation.

Heat Extraction Rate

The rate of heat transfer from the ground will be affected by the quality of the ground, geology, ground temperature, the duration of heat extraction, etc. However, a conservative guideline figure for heat absorption is 20 W/m for a trench and 25 W/m for boreholes.

Heat extraction values are provided in EN 15450:2007 for 1,800 and 2,400 hours operation of the heat pump per year.

Proximity to buildings and vegetation can hinder ground thermal recovery due to reduced solar exposure. A 10-metre offset is recommended to preserve efficiency, support ground recovery, and ensure safe clearance for infrastructure.

Horizontal Trench

Horizontal systems are generally cheaper than vertical loops but require a significant amount of land, so are rarely sized above 150 kW.

The average heat extraction rate per square metre of ground collector area ranges from 10 W/m² for dry non-cohesive soil (over 1,800 h) to 40 W/m² for saturated sand (over 1,800 h). A 100 kW system would therefore require anywhere between 10,000 m² to just 2,500 m² of land. Extending the operating hours would increase the land area required.

Vertical Loops

Vertical closed loop solutions are used for medium sized systems ranging from 100 to 1,000 kW in the UK. Boreholes are drilled 100–160 mm diameter in the ground with depths 15 to 200 m at spacings of 4 to 15 m. To avoid thermal interference the minimum distance between boreholes is normally 5 to 6 m. Larger systems with extended operation may need spacing increased to 10-15 metres to maintain efficient heat extraction.

For vertical loops or boreholes, the following values from EN 15450 can be used if the soil type is known.

| Ground Type | Typical Heat Extraction (W/m) | |

|---|---|---|

| 1800 h | 2400 h | |

| Sand (dry) | <25 | <20 |

| Sand (saturated) | 65-80 | 55-65 |

| Clay (moist) | 35-50 | 30-40 |

| Limestone | 55-70 | 45-60 |

| Sandstone | 65-80 | 55-65 |

The above figures are for a single system with up to 5 bores holes and an annual mean external temperature range between 9 and 11 °C. Thermal conductivity testing is a must to determine the heat transfer potential for a given location and should always be undertaken before system design starts.

Read the Homemicro.co.uk article on thermal collector pipes (here )

System Design

It is generally uneconomic to size a heat pump to meet the peak demand as the sole heat source (a monovalent system) so sizing and selection to match the system is important.

Most systems are bivalent - that is, heat is generated by two separate means as alternative heat providers. There are two typical design arrangements.

In one configuration the heat pump satisfies the design load for much of the time. However, when the ambient temperature is too low or a fast heat-up is required, the heat pump is switched off and the alternative heat generator is used. This means that the alternative heat source must be sized for the peak load.

An alternative bivalent design runs the heat pump continuously with the second generator operating simultaneously when the heat pump cannot meet the total heating load. With this alternative design, the heat pump is usually selected to match the base load, ensuring near constant operation to maximise return on the investment costs. For an existing building, the base load can be accurately determined by charting energy consumption, ideally logged on an hourly or even half-hourly interval. If this information is not available, the heat pump should be sized to match the building heat loss above an outside air temperature of 4 °C and the second generator sized to match the building heat loss between 4 °C and the design outside air temperature.

In larger systems, buffer vessels/themal stores will be used to smooth out the operation of the heat pump. See Homemicro.co.uk's article on buffer vessel sizing

Buffer Vessel Sizing

The volume (litre) of a buffer vessel is dependent on system use and can be calculated from:

- V (intermittent use) = heat load (kW) x 25

- V (continuous use) = heat load (kW) x 80

Homemicro.co.uk's vessel sizing (here )

GSHP CoP

GSHP efficiency is dependent upon the operating temperatures. Typical COP's for differing water to water heat pumps systems:

- Floor htg at 30/35 °C - 4.0

- Radiators at 35/45 °C - 3.5

- Radiators at 50/60 °C - 2.5

Installation Cost

GSHP installation costs range from about £800-£1200 per kW of peak heat output (excluding the distribution system cost). A typical domestic 8-12 kW GSHP system would cost between £6,000 and £12,000 excluding the distribution system.

A message from a sponsor

Ground Source Heat Pump (GSHP) id: lzc-11 (v.7.0)